1.EDM yam ntxwv ntawm graphite cov ntaub ntawv.

1.1.Discharge machining ceev.

Graphite yog cov khoom siv uas tsis yog xim hlau nrog lub siab melting point ntawm 3, 650 ° C, thaum tooj liab muaj qhov melting point ntawm 1, 083 ° C, yog li cov graphite electrode tuaj yeem tiv taus ntau dua tam sim no.

Thaum qhov chaw tawm thiab qhov ntsuas ntawm electrode loj dua, qhov zoo ntawm kev ua haujlwm siab ntxhib machining ntawm cov khoom siv graphite yog qhov pom tseeb dua.

Lub thermal conductivity ntawm graphite yog 1/3 ntawm tooj liab, thiab cov cua sov tsim thaum lub sij hawm tso tawm yuav siv tau los tshem tawm cov ntaub ntawv hlau zoo dua. Yog li ntawd, kev ua tau zoo ntawm graphite yog siab dua li ntawm tooj liab electrode hauv nruab nrab thiab kev ua haujlwm zoo.

Raws li cov kev paub dhau los, qhov tso tawm ceev ntawm graphite electrode yog 1.5 ~ 2 zaug sai dua li ntawm tooj liab electrode raws li kev siv kom raug.

1.2.Electrode noj.

Graphite electrode muaj tus cwj pwm uas tuaj yeem tiv taus qhov siab tam sim no, ntxiv rau, nyob rau hauv qhov xwm txheej ntawm qhov tsim nyog roughing qhov chaw, nrog rau cov pa roj carbon steel workpieces tsim thaum lub sij hawm machining tshem tawm cov ntsiab lus thiab ua hauj lwm kua ntawm kub decomposition ntawm carbon hais, cov polarity nyhuv, nyob rau hauv qhov kev txiav txim ntawm ib feem tshem tawm cov ntsiab lus, cov pa roj carbon particles yuav adheres rau lub electrode txheej nyob rau hauv ib tug me me qhov chaw nyob rau hauv cov ntaub ntawv. machining, lossis txawm tias "zero pov tseg".

Lub ntsiab electrode poob hauv EDM los ntawm kev ua haujlwm tsis zoo. Txawm hais tias qhov poob qis yog siab nyob rau hauv cov xwm txheej ntawm kev ua tiav, qhov poob tag nrho kuj tseem tsawg vim qhov nyiaj me me machining tshwj tseg rau qhov chaw.

Feem ntau, qhov poob ntawm graphite electrode yog tsawg tshaj li ntawm tooj liab electrode nyob rau hauv ntxhib machining ntawm loj tam sim no thiab me ntsis ntau tshaj li ntawm tooj liab electrode nyob rau hauv tiav machining. Cov electrode poob ntawm graphite electrode zoo ib yam.

1.3.Qhov zoo.

Cov kab uas hla ntawm cov khoom siv graphite ncaj qha cuam tshuam rau qhov roughness ntawm EDM. Qhov me me ntawm txoj kab uas hla yog, qhov qis ntawm qhov roughness tuaj yeem tau txais.

Ob peb xyoos dhau los siv particle phi 5 microns nyob rau hauv txoj kab uas hla graphite cov ntaub ntawv, qhov zoo tshaj plaws nto tsuas yog ua tiav VDI18 edm (Ra0.8 microns), tam sim no cov nplej txoj kab uas hla ntawm graphite cov ntaub ntawv tau ua tiav nyob rau hauv 3 microns ntawm phi, qhov zoo tshaj plaws nto yuav ua tau ruaj khov VDI12 edm (Ra0.4 mu m) los yog ntau dua sophisticated iav, tab sis sophisticated qib.

Cov khoom siv tooj liab muaj qhov tsis zoo thiab cov qauv compact, thiab tuaj yeem ua tiav nyob rau hauv cov xwm txheej nyuaj. Qhov saum npoo roughness yuav tsawg dua Ra0.1 m, thiab nws tuaj yeem ua tiav los ntawm daim iav.

Yog li, yog tias lub tshuab hluav taws xob tawm mus nrhiav qhov chaw zoo heev, nws tsim nyog siv cov khoom siv tooj liab li electrode, uas yog qhov zoo ntawm tooj liab electrode tshaj graphite electrode.

Tab sis tooj liab electrode nyob rau hauv qhov teeb meem ntawm qhov loj tam sim no, lub electrode nto yog ib qho yooj yim los ua ntxhib, tshwm txawm tawg, thiab graphite cov ntaub ntawv yuav tsis muaj qhov teeb meem no, qhov saum npoo roughness yuav tsum tau rau VDI26 (Ra2.0 microns) txog pwm ua, siv graphite electrode yuav ua tau los ntawm ntxhib mus rau zoo ua, realizes lub uniform nto nyhuv, qhov defects.

Tsis tas li ntawd, vim muaj cov qauv sib txawv ntawm graphite thiab tooj liab, qhov chaw tawm ntawm corrosion ntawm graphite electrode yog ntau dua li ntawm tooj liab electrode. Yog li ntawd, thaum tib qhov chaw roughness ntawm VDI20 los yog saum toj no yog ua tiav, lub nto granularity ntawm lub workpiece ua tiav los ntawm graphite electrode yog ntau txawv, thiab no grain nto nyhuv yog zoo dua li qhov paug nto nyhuv ntawm tooj liab electrode.

1.4.Qhov tseeb machining.

Lub coefficient ntawm thermal expansion ntawm graphite khoom yog me me, lub coefficient ntawm thermal expansion ntawm tooj liab cov ntaub ntawv yog 4 lub sij hawm ntawm graphite cov ntaub ntawv, yog li nyob rau hauv lub tso tawm, graphite electrode tsis tshua muaj deformation dua tooj liab electrode, uas muaj peev xwm kom tau ntau ruaj khov thiab txhim khu kev qha ua raug.

Tshwj xeeb tshaj yog thaum sib sib zog nqus thiab nqaim tav yog ua tiav, qhov kub hauv zos ua rau tooj liab electrode khoov tau yooj yim, tab sis graphite electrode tsis.

Rau tooj liab electrode nrog ib tug loj qhov tob-inch ratio, ib tug tej yam thermal expansion tus nqi yuav tsum tau them nyiaj rau kho qhov luaj li cas thaum lub sij hawm machining chaw, thaum graphite electrode tsis tas yuav tsum tau.

1.5.Electrode hnyav.

Cov khoom siv graphite yog tsawg dua tooj liab, thiab qhov hnyav ntawm graphite electrode ntawm tib lub ntim tsuas yog 1/5 ntawm cov tooj liab electrode.

Nws tuaj yeem pom tau tias kev siv graphite yog qhov tsim nyog rau cov electrode nrog lub ntim loj, uas txo cov load ntawm spindle ntawm EDM tshuab cuab yeej. Cov electrode yuav tsis ua rau tsis yooj yim rau clamping vim nws qhov hnyav loj, thiab nws yuav tsim deflection hloov chaw hauv kev ua, thiab lwm yam. Nws tuaj yeem pom tau tias nws tseem ceeb heev rau kev siv graphite electrode hauv kev ua pwm loj.

1.6.Electrode manufacturing nyuaj.

Lub machining kev ua tau zoo ntawm cov khoom siv graphite yog qhov zoo. Kev txiav tsis kam tsuas yog 1/4 ntawm tooj liab. Raws li kev ua haujlwm raug, qhov ua tau zoo ntawm milling graphite electrode yog 2 ~ 3 npaug ntawm tooj liab electrode.

Graphite electrode yog ib qho yooj yim los ntxuav lub kaum sab xis, thiab nws tuaj yeem siv los ua cov khoom ua haujlwm uas yuav tsum tau ua tiav los ntawm ntau lub electrodes rau hauv ib qho electrode.

Cov qauv tshwj xeeb ntawm cov khoom siv graphite tiv thaiv burrs los ntawm qhov tshwm sim tom qab electrode milling thiab tsim, uas tuaj yeem ua tau raws li qhov yuav tsum tau siv thaum cov burrs tsis yooj yim tshem tawm hauv cov qauv tsim, yog li tshem tawm cov txheej txheem ntawm phau ntawv polishing ntawm electrode thiab zam qhov hloov pauv thiab qhov yuam kev loj los ntawm polishing.

Nws yuav tsum tau muab sau tseg tias, vim hais tias graphite yog plua plav tsub zuj zuj, milling graphite yuav tsim cov plua plav ntau, yog li lub tshuab milling yuav tsum muaj lub foob thiab cov khoom siv plua plav.

Yog tias nws tsim nyog siv edM los ua cov graphite electrode, nws cov kev ua haujlwm tsis zoo li cov khoom siv tooj liab, txiav ceev yog li 40% qeeb dua tooj liab.

1.7.Electrode installation thiab siv.

Cov khoom siv graphite muaj cov khoom sib txuas zoo. Nws tuaj yeem siv los txuas graphite nrog cov khoom siv los ntawm milling cov electrode thiab tawm, uas tuaj yeem txuag cov txheej txheem ntawm machining ntsia hlau qhov ntawm cov khoom siv electrode thiab txuag lub sijhawm ua haujlwm.

Cov khoom siv graphite kuj yog nkig, tshwj xeeb tshaj yog me me, nqaim thiab ntev electrode, uas yooj yim tawg thaum raug rau sab nraud quab yuam thaum siv, tab sis tuaj yeem paub tam sim ntawd tias cov electrode puas lawm.

Yog tias nws yog tooj liab electrode, nws tsuas yog khoov thiab tsis tawg, uas yog qhov txaus ntshai heev thiab nyuaj rau nrhiav tau hauv cov txheej txheem ntawm kev siv, thiab nws yuav yooj yim ua rau cov seem ntawm lub workpiece.

1.8.Nqe.

Cov khoom siv tooj liab yog cov khoom siv tsis tau txuas ntxiv dua tshiab, tus nqi sib txawv yuav dhau los ua ntau thiab kim dua, thaum tus nqi ntawm cov khoom siv graphite zoo li ruaj khov.

Cov khoom siv tooj liab nce nyob rau xyoo tas los no, cov tuam txhab loj ntawm graphite txhim kho cov txheej txheem hauv kev tsim cov graphite ua rau nws qhov kev sib tw kom zoo dua, tam sim no, nyob rau hauv tib lub ntim, feem ntau ntawm cov khoom siv hluav taws xob graphite tus nqi thiab tus nqi ntawm cov khoom siv tooj liab electrode yog heev, tab sis cov graphite tuaj yeem ua tau zoo, dua li kev siv tooj liab electrode kom txuag tau ntau lub sijhawm ua haujlwm.

Txhawm rau suav nrog, ntawm 8 edM tus yam ntxwv ntawm graphite electrode, nws qhov zoo yog qhov pom tseeb: kev ua haujlwm ntawm milling electrode thiab tso tawm yog qhov zoo dua li ntawm tooj liab electrode; loj electrode muaj qhov hnyav me me, zoo qhov ruaj khov, nyias electrode tsis yooj yim rau deform, thiab kev ntxhib los mos zoo dua li tooj liab electrode.

Qhov tsis zoo ntawm cov khoom siv graphite yog tias nws tsis haum rau kev ua haujlwm zoo ntawm qhov chaw tawm hauv qab VDI12 (Ra0.4 m), thiab qhov ua tau zoo ntawm kev siv edM los ua electrode yog tsawg.

Txawm li cas los xij, los ntawm kev pom zoo, ib qho ntawm cov laj thawj tseem ceeb cuam tshuam rau kev txhawb nqa cov khoom siv graphite hauv Suav teb yog qhov tshwj xeeb graphite ua tshuab yog xav tau rau milling electrodes, uas tso rau pem hauv ntej cov kev cai tshiab rau kev ua cov cuab yeej ntawm cov lag luam pwm, qee lub lag luam me yuav tsis muaj qhov xwm txheej no.

Feem ntau, qhov zoo ntawm graphite electrodes npog feem ntau ntawm edM ua lub sijhawm, thiab tsim nyog rau kev nyiam thiab siv, nrog rau cov txiaj ntsig ntev ntev. Qhov tsis txaus ntawm kev ua haujlwm zoo tuaj yeem tsim los ntawm kev siv tooj liab electrodes.

2.Kev xaiv cov khoom siv graphite electrode rau EDM

Rau cov ntaub ntawv graphite, feem ntau muaj plaub qhov ntsuas hauv qab no uas ncaj qha txiav txim siab qhov ua tau zoo ntawm cov ntaub ntawv:

1) Qhov nruab nrab particle txoj kab uas hla ntawm cov khoom

Qhov nruab nrab particle txoj kab uas hla ntawm cov khoom ncaj qha cuam tshuam rau qhov paug ntawm cov khoom.

Qhov me me qhov nruab nrab ntawm cov khoom siv graphite yog, qhov sib txawv ntawm qhov paug tawm ntau dua, qhov ruaj khov ntawm qhov paug tawm yog qhov zoo, qhov zoo ntawm qhov chaw zoo, thiab qhov poob qis dua.

Qhov loj dua qhov nruab nrab particle loj yog, qhov kev tshem tawm zoo dua tuaj yeem tau txais hauv kev ua haujlwm ntxhib, tab sis qhov cuam tshuam ntawm kev ua tiav yog qhov tsis zoo thiab cov electrode poob loj.

2) Lub zog khoov ntawm cov khoom

Lub zog flexural ntawm cov khoom siv yog qhov cuam tshuam ncaj qha ntawm nws lub zog, qhia qhov nruj ntawm nws cov qauv sab hauv.

Cov khoom siv nrog lub zog siab muaj qhov ua tau zoo ntawm kev ua haujlwm. Rau cov electrode nrog high precision, cov khoom siv nrog lub zog zoo yuav tsum raug xaiv kom deb li deb tau.

3) Shore hardness ntawm cov khoom

Graphite nyuaj dua li cov ntaub ntawv hlau, thiab qhov poob ntawm cov cuab yeej txiav yog ntau dua li ntawm cov hlau txiav.

Nyob rau tib lub sij hawm, lub siab hardness ntawm graphite cov ntaub ntawv nyob rau hauv lub paug paug tswj yog zoo dua.

4) Inherent resistivity ntawm cov khoom

Tus nqi tso tawm ntawm cov khoom siv graphite nrog qhov muaj peev xwm tiv taus siab yuav qeeb dua qhov uas tsis muaj qhov tsis kam.

Qhov siab dua qhov inherent resistivity, qhov me me ntawm electrode poob, tab sis qhov siab dua qhov inherent resistivity, qhov ruaj khov ntawm qhov paug yuav cuam tshuam.

Tam sim no, muaj ntau ntau qib sib txawv ntawm graphite muaj los ntawm lub ntiaj teb ua lag luam graphite.

Feem ntau raws li qhov nruab nrab particle txoj kab uas hla ntawm graphite cov ntaub ntawv yuav tsum tau muab cais, particle inch ≤ 4 m yog txhais raws li zoo graphite, hais nyob rau hauv 5 ~ 10 m yog txhais raws li nruab nrab graphite, hais nyob rau hauv 10 m saum toj no yog txhais raws li ntxhib graphite.

Qhov me me ntawm txoj kab uas hla yog, cov khoom siv kim dua, cov khoom siv graphite tsim nyog tuaj yeem xaiv raws li qhov yuav tsum tau ua thiab tus nqi ntawm EDM.

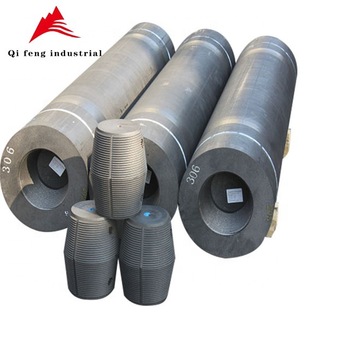

3.Fabrication ntawm graphite electrode

Lub graphite electrode feem ntau yog ua los ntawm milling.

Los ntawm qhov pom ntawm kev siv thev naus laus zis, graphite thiab tooj liab yog ob yam khoom sib txawv, thiab lawv cov yam ntxwv sib txawv yuav tsum tau ua kom zoo.

Yog tias cov graphite electrode tau ua tiav los ntawm cov txheej txheem ntawm tooj liab electrode, cov teeb meem yuav tshwm sim, xws li kev puas tsuaj ntawm daim ntawv, uas yuav tsum tau siv cov cuab yeej txiav tsim nyog thiab txiav tsis.

Machining graphite electrode dua li tooj liab electrode cuab yeej hnav, ntawm kev xav txog kev lag luam, kev xaiv cov cuab yeej carbide yog qhov kev lag luam tshaj plaws, xaiv pob zeb diamond txheej cuab yeej (hu ua graphite riam) tus nqi yog kim dua, tab sis pob zeb diamond txheej cuab yeej siv lub neej ntev, kev ua haujlwm siab, cov txiaj ntsig kev lag luam tag nrho yog qhov zoo.

Qhov loj ntawm lub kaum sab xis ntawm lub cuab yeej tseem cuam tshuam rau nws lub neej kev pab cuam, 0 ° pem hauv ntej lub kaum sab xis ntawm lub cuab yeej yuav nce mus txog 50% siab tshaj 15 ° pem hauv ntej Lub kaum sab xis ntawm lub cuab yeej kev pab cuam lub neej, txiav kev ruaj ntseg kuj zoo dua, tab sis qhov ntau dua lub kaum sab xis, qhov zoo dua ntawm machining nto, kev siv 15 ° Lub kaum sab xis ntawm lub cuab yeej tuaj yeem ua tiav qhov zoo tshaj plaws machining nto.

Kev txiav ceev hauv machining tuaj yeem hloov kho raws li cov duab ntawm cov electrode, feem ntau yog 10m / min, zoo ib yam li machining ntawm txhuas lossis yas, cov cuab yeej txiav tuaj yeem ncaj qha rau ntawm thiab tawm ntawm qhov chaw ua haujlwm hauv kev ua haujlwm ntxhib, thiab qhov tshwm sim ntawm lub kaum sab xis thiab tawg yog yooj yim tshwm sim hauv kev ua tiav, thiab txoj kev ntawm lub teeb riam ceev ceev taug kev yog feem ntau siv.

Graphite electrode nyob rau hauv cov txheej txheem txiav yuav tsim cov plua plav ntau, txhawm rau kom tsis txhob muaj cov khoom siv graphite inhaled tshuab ntxaiv thiab ntsia hlau, muaj ob txoj hauv kev tam sim no, ib qho yog siv lub tshuab tshwj xeeb graphite ua, lwm qhov yog qhov chaw ua haujlwm zoo tib yam, nruab nrog cov khoom siv plua plav tshwj xeeb.

Qhov tshwj xeeb graphite siab ceev milling tshuab nyob rau hauv kev ua lag luam muaj kev ua haujlwm siab milling thiab tuaj yeem ua kom tiav cov kev tsim cov electrodes nyuaj nrog kev ua haujlwm siab thiab zoo nto zoo.

Yog tias EDM xav tau los ua graphite electrode, nws raug nquahu kom siv cov khoom siv graphite zoo nrog cov kab me me.

Lub machining kev ua tau zoo ntawm graphite tsis zoo, qhov me me ntawm particle inch yog, qhov siab dua qhov kev ua tau zoo tuaj yeem tau txais, thiab cov teeb meem txawv txav xws li cov hlau tsis tu ncua thiab cov npoo npoo tuaj yeem zam tau.

4.EDM tsis muaj graphite electrode

Kev xaiv ntawm EDM tsis muaj graphite thiab tooj liab sib txawv heev.

Cov tsis muaj EDM feem ntau suav nrog tam sim no, mem tes dav, mem tes sib txawv thiab polarity.

Cov hauv qab no piav qhia txog lub hauv paus rau kev siv lub ntsiab lus ntawm cov kev txwv loj no.

Tam sim no qhov ceev ntawm graphite electrode feem ntau yog 10 ~ 12 A / cm2, loj dua li ntawm tooj liab electrode. Yog li ntawd, nyob rau hauv qhov ntau ntawm tam sim no tso cai rau hauv cheeb tsam sib thooj, qhov loj dua qhov tam sim no raug xaiv, qhov ceev ntawm graphite tso tawm yuav ua tau, qhov me me ntawm electrode poob yuav yog, tab sis qhov roughness ntawm qhov chaw yuav thicker.

Qhov loj ntawm lub mem tes dav yog, qhov qis ntawm electrode poob yuav yog.

Txawm li cas los xij, qhov dav pulse loj dua yuav ua rau kev ua haujlwm ruaj khov dua, thiab kev ua haujlwm qeeb qeeb thiab nto rougher.

Txhawm rau kom ntseeg tau tias tsis tshua muaj hluav taws xob poob thaum lub sijhawm ua haujlwm ntxhib, feem ntau siv cov mem tes dav dav, uas tuaj yeem paub txog qhov poob qis ntawm graphite electrode thaum tus nqi ntawm 100 thiab 300 US.

Txhawm rau kom tau txais qhov zoo ntawm qhov chaw thiab qhov tso tawm ruaj khov, yuav tsum xaiv qhov dav me me me me.

Feem ntau, cov mem tes dav ntawm graphite electrode yog li 40% tsawg dua li ntawm tooj liab electrode.

Qhov sib txawv ntawm cov mem tes feem ntau cuam tshuam rau qhov tso tawm machining ceev thiab machining stability. Qhov ntau dua tus nqi, qhov zoo dua qhov machining stability yuav yog, uas yuav pab tau kom tau zoo dua nto uniformity, tab sis lub machining ceev yuav raug txo.

Nyob rau hauv cov xwm txheej ntawm kev ua kom muaj kev ruaj ntseg, kev ua haujlwm siab dua tuaj yeem tau txais los ntawm kev xaiv qhov sib txawv me me, tab sis thaum lub xeev tso tawm tsis ruaj khov, kev ua haujlwm siab dua tuaj yeem tau txais los ntawm kev xaiv qhov sib txawv ntawm cov mem tes loj.

Hauv graphite electrode discharge machining, pulse gap thiab mem tes dav feem ntau yog teem rau ntawm 1: 1, thaum nyob rau hauv tooj liab electrode machining, mem tes sib txawv thiab mem tes dav feem ntau yog teem ntawm 1: 3.

Raws li kev ua haujlwm ruaj khov graphite, qhov sib piv ntawm pulse kis thiab mem tes dav tuaj yeem hloov kho rau 2: 3.

Nyob rau hauv cov ntaub ntawv ntawm me me mem tes clearance, nws yog ib qho zoo los tsim ib txheej txheej ntawm electrode nto, uas yuav pab tau kom txo tau cov electrode poob.

Kev xaiv polarity ntawm graphite electrode hauv EDM yog qhov pib zoo ib yam li tooj liab electrode.

Raws li cov nyhuv polarity ntawm EDM, qhov zoo polarity machining feem ntau yog siv thaum machining tuag steel, uas yog, lub electrode txuas nrog lub zoo ncej ntawm lub hwj chim mov, thiab lub workpiece yog txuas nrog rau qhov tsis zoo ncej ntawm lub hwj chim mov.

Siv cov tam sim no loj thiab mem tes dav, xaiv qhov zoo polarity machining tuaj yeem ua tiav tsis tshua muaj hluav taws xob poob. Yog hais tias lub polarity tsis ncaj ncees lawm, lub electrode poob yuav loj heev.

Tsuas yog thaum qhov saum npoo yuav tsum tau ua kom zoo ua haujlwm tsawg dua VDI18 (Ra0.8 m) thiab cov mem tes dav me me, kev ua tsis zoo polarity yog siv kom tau txais qhov zoo ntawm qhov zoo, tab sis cov electrode poob loj.

Tam sim no CNC edM tshuab cuab yeej tau nruab nrog graphite paug machining tsis.

Kev siv hluav taws xob tsis zoo yog qhov ntse thiab tuaj yeem tsim tau los ntawm cov kws tshaj lij ntawm cov cuab yeej siv tshuab.

Feem ntau, lub tshuab tuaj yeem txhim kho qhov ua tau zoo ntawm cov khoom siv los ntawm kev xaiv cov khoom khub, daim ntawv thov hom, tus nqi ntawm qhov roughness thiab inputting qhov chaw ua, ua qhov tob, electrode loj scaling, thiab lwm yam thaum lub sij hawm programming.

Teem rau graphite electrode ntawm edm tshuab cuab yeej tsev qiv ntawv nplua nuj ua tsis tau, cov khoom siv tuaj yeem xaiv hauv cov graphite ntxhib, graphite, graphite sib haum rau ntau yam khoom siv ua haujlwm, kom subdivide hom ntawv thov rau tus qauv, sib sib zog nqus zawj, ntse taw tes, thaj tsam loj, kab noj hniav loj, xws li nplua, kuj muab kev poob qis, kev xaiv ntawm cov txheej txheem ntau yam ua ntej.

5. Cov lus xaus

Cov khoom siv graphite electrode tshiab yog tsim nyog ua kom muaj zog thiab nws qhov zoo yuav maj mam lees paub thiab lees txais los ntawm kev lag luam pwm hauv tsev.

Kev xaiv kom raug ntawm graphite electrode cov ntaub ntawv thiab kev txhim kho ntawm cov kev sib txuas thev naus laus zis yuav ua rau muaj kev ua haujlwm siab, zoo siab thiab tus nqi qis rau cov lag luam tsim pwm.

Post lub sij hawm: Dec-04-2020