Ultra-siab zog graphite electrodes, los ntawm kev hloov tooj liab electrodes nrog graphite electrodes rau pwm manufacturing, ho txo lub pwm tsim voj voog, txhim khu kev ua hauj lwm tsim, thiab txo cov pwm raug nqi. Nyob rau hauv xyoo tas los no, nrog rau kev taw qhia ntawm precision pwm thiab high-efficiency pwm (nrog rau cov pwm luv luv), tib neeg cov kev cai rau pwm tsim tau nce siab dua. Vim muaj ntau yam kev txwv ntawm tooj liab electrodes lawv tus kheej, Nws tau nce zuj zus ua tsis tau raws li txoj kev loj hlob ntawm kev lag luam pwm. Graphite, raws li cov khoom siv EDM electrode, tau siv dav hauv kev lag luam pwm vim nws qhov zoo xws li kev ua haujlwm siab, lub teeb yuag, tsim nrawm, tsis tshua muaj qhov nthuav dav, tsis tshua muaj kev poob thiab hnav yooj yim. Nws yog inevitable uas nws yuav hloov tooj liab electrodes.

1. Cov yam ntxwv ntawm cov khoom siv hluav taws xob graphite

CNC machining nta ceev ceev ceev, machinability siab thiab hnav tau yooj yim. Kev ua haujlwm ceev ntawm cov tshuab graphite yog 3 mus rau 5 npaug ntawm tooj liab electrodes, thiab kev ua haujlwm ceev yog qhov tshwj xeeb tshaj yog. Ntxiv mus, nws lub zog yog siab heev. Rau ultra-siab (50 mus rau 90mm) thiab ultra-nyias (0.2 txog 0.5mm) electrodes, lawv tsis nquag deformation thaum ua. Ntxiv mus, nyob rau hauv ntau rooj plaub, cov khoom yuav tsum muaj ib tug zoo nkauj zoo nkauj nyhuv. Qhov no yuav tsum tau hais tias thaum ua electrodes, lawv yuav tsum tau ua raws li ib tug txiv neej electrodes li sai tau. Txawm li cas los xij, muaj ntau lub kaum sab xis clearings thaum lub sij hawm tsim cov txiv neej electrodes. Vim yog qhov yooj yim trimming cuab yeej ntawm graphite, qhov teeb meem no tuaj yeem daws tau yooj yim thiab cov xov tooj ntawm cov electrodes tuaj yeem txo qis, uas tooj liab electrodes tsis tuaj yeem ua tiav.

2. Kev sib sau nrawm EDM, me me thermal expansion thiab poob qis: Vim yog qhov zoo ntawm cov hluav taws xob conductivity ntawm graphite dua li tooj liab, nws qhov paug tawm sai dua li tooj liab, yog 3 mus rau 5 npaug ntawm tooj liab. Tsis tas li ntawd, nws tuaj yeem tiv taus qhov tam sim no loj heev thaum lub sij hawm tawm, uas yog qhov zoo dua rau kev siv hluav taws xob tsis zoo. Lub caij no, nyob rau hauv tib lub ntim, qhov hnyav ntawm graphite yog 1/5 npaug ntawm tooj liab, uas txo cov load ntawm EDM. Nws muaj txiaj ntsig zoo hauv kev tsim cov electrodes loj thiab cov txiv neej electrodes. Qhov kub sublimation ntawm graphite yog 4200 ℃, uas yog 3 mus rau 4 npaug ntawm tooj liab (lub sublimation kub ntawm tooj liab yog 1100 ℃). Thaum kub kub, hloov

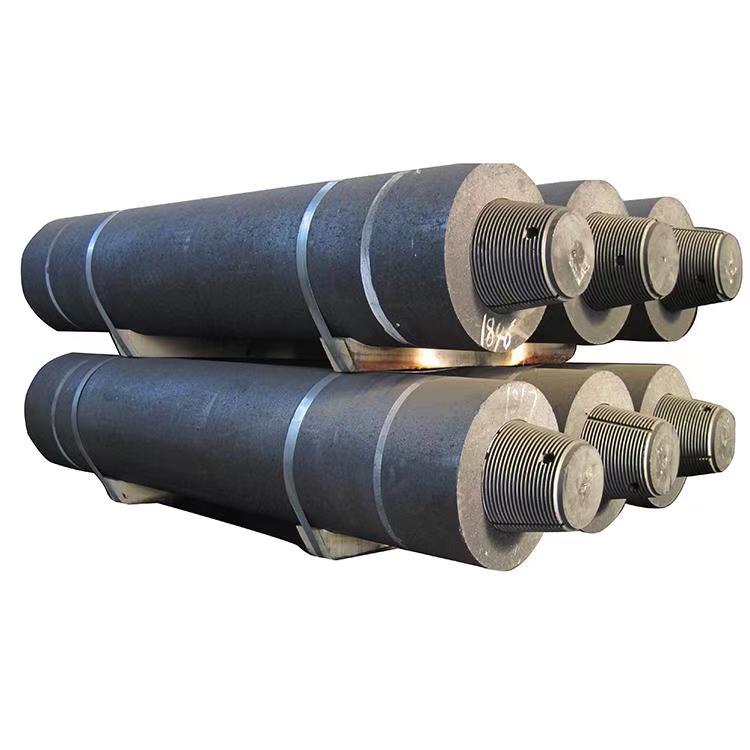

Ultra-siab zog graphite electrode

Nws yog qhov me me heev (1/3 txog 1/5 ntawm tooj liab nyob rau hauv tib lub zog hluav taws xob) thiab tsis soften. Lub zog tso tawm tuaj yeem hloov mus rau qhov chaw ua haujlwm tau zoo thiab siv tsawg. Vim tias lub zog ntawm graphite tiag tiag nce ntawm qhov kub thiab txias, nws tuaj yeem txo qhov kev poob qis (qhov poob ntawm graphite yog 1/4 ntawm cov tooj liab), ua kom muaj kev ua haujlwm zoo.

3. Lub teeb yuag thiab tus nqi qis: Hauv cov nqi tsim khoom ntawm cov pwm pwm, CNC machining lub sij hawm, EDM lub sij hawm, thiab electrode hnav ntawm cov electrodes account rau feem ntau ntawm tag nrho cov nqi, thiab tag nrho cov no yog txiav txim los ntawm cov khoom siv electrode nws tus kheej. Piv nrog tooj liab, machining ceev thiab EDM ceev ntawm graphite yog ob qho tib si 3 mus rau 5 npaug ntawm tooj liab. Lub caij no, cov yam ntxwv ntawm kev hnav tsawg tsawg thiab kev tsim cov graphite electrode tuaj yeem txo cov naj npawb ntawm cov electrodes, yog li txo cov khoom siv thiab lub sijhawm ua haujlwm ntawm cov electrodes. Tag nrho cov no tuaj yeem txo cov nqi tsim khoom ntawm pwm

2. Kev xav tau thiab cov yam ntxwv ntawm kev siv tshuab thiab hluav taws xob ua haujlwm ntawm graphite electrodes

1. Kev tsim cov khoom siv hluav taws xob: Kev tshaj lij graphite electrode ntau lawm tsuas yog siv cov cuab yeej siv tshuab ceev rau kev ua haujlwm. Cov cuab yeej siv tshuab yuav tsum muaj kev ruaj ntseg zoo, nrog kev sib txuam thiab ruaj khov peb-axis txav tsis muaj kev vibration. Tsis tas li ntawd, kev sib hloov qhov tseeb ntawm cov khoom xws li lub ntsiab ncej yuav tsum zoo li qhov ua tau. Cov electrode kuj tuaj yeem ua tiav ntawm cov cuab yeej siv tshuab dav dav, tab sis cov txheej txheem ntawm kev sau cov cuab yeej txoj kev sib txawv ntawm cov tooj liab electrodes.

2.EDM hluav taws xob tawm machining graphite electrodes yog carbon electrodes. Vim tias graphite muaj cov khoom siv hluav taws xob zoo, nws tuaj yeem txuag tau ntau lub sijhawm hauv hluav taws xob tawm tshuab, uas kuj yog ib qho laj thawj vim li cas graphite siv los ua electrode.

3. Cov yam ntxwv ntawm Graphite Electrodes: Muaj graphite nyuaj thiab nkig, ua rau hnyav hnyav rau cov cuab yeej thaum CNC machining. Feem ntau, nws raug pom zoo kom siv cov cuab yeej coated nrog nyuaj alloy lossis pob zeb diamond. Thaum ntxhib machining graphite, lub cuab yeej tuaj yeem muab tso ncaj qha rau ntawm qhov chaw ua haujlwm. Txawm li cas los xij, thaum lub sijhawm ua tiav machining, txhawm rau tiv thaiv chipping thiab tawg, lub teeb lub teeb thiab txoj kev nrawm nrawm yog feem ntau tau txais.

Feem ntau hais lus, graphite tsis tshua tawg thaum txiav qhov tob tsawg dua 0.2 hli, thiab qhov zoo ntawm sab phab ntsa tuaj yeem tau txais. Cov plua plav generated thaum lub sij hawm CNC machining ntawm graphite electrodes yog qhov loj thiab tuaj yeem cuam tshuam cov kev taw qhia rails, txhuas screws thiab spindles ntawm lub tshuab cuab yeej, thiab lwm yam. Graphite hmoov yog ib yam khoom uas muaj rhiab heev rau cov tshuaj tiv thaiv. Nws resistivity hloov nyob rau hauv ib puag ncig sib txawv, lub ntsiab lus nws tus nqi kuj txawv. Txawm li cas los xij, muaj ib yam uas tseem nyob tas li: graphite hmoov yog ib qho ntawm cov khoom siv zoo heev uas tsis yog xim hlau. Tsuav yog cov graphite hmoov khaws cia rau hauv ib qho khoom siv insulating yam tsis muaj kev cuam tshuam, zoo li cov xov nyias, nws tseem yuav tau hluav taws xob. Tab sis tus nqi kuj yog dab tsi? Tsis muaj daim duab meej meej rau tus nqi no, vim tias qhov zoo ntawm graphite hmoov sib txawv, thiab tus nqi tsis kam ntawm graphite hmoov siv hauv cov khoom sib txawv thiab ib puag ncig kuj yuav txawv.

Tej zaum koj yuav tsis paub tias high-purity graphite hmoov kuj muaj kev siv hluav taws xob:

Feem ntau, roj hmab yog insulating. Yog tias xav tau hluav taws xob conductivity, cov khoom siv hluav taws xob yuav tsum tau ntxiv. Graphite hmoov muaj cov khoom siv hluav taws xob zoo heev thiab lubricating demolding zog. Graphite yog ua tiav rau hauv graphite hmoov, uas muaj lubricating zoo thiab conductive zog. Qhov siab dua qhov purity ntawm graphite hmoov, qhov zoo dua nws cov kev ua tau zoo. Ntau cov khoom siv roj hmab tshwj xeeb xav tau cov roj hmab conductive. Tom qab ntawd, graphite hmoov puas tuaj yeem ntxiv rau roj hmab kom ua hluav taws xob? Cov lus teb yog yog, tab sis kuj tseem muaj lus nug: Dab tsi yog qhov feem ntawm graphite hmoov hauv roj hmab? Qee lub tuam txhab siv qhov feem ntawm tsis pub tshaj 30%, uas yog siv rau cov khoom siv roj hmab hnav-resistant xws li cov log tsheb, thiab lwm yam. Tseem muaj cov chaw tsim khoom roj hmab tshwj xeeb uas siv feem ntawm 100%. Tsuas yog cov khoom no tuaj yeem ua hluav taws xob. Lub hauv paus ntsiab lus ntawm conductivity yog tias tus neeg xyuas pib tsis tuaj yeem cuam tshuam, ib yam li cov xaim. Yog tias nws cuam tshuam hauv nruab nrab, nws yuav tsis raug hluav taws xob. Lub conductive graphite hmoov nyob rau hauv conductive roj hmab yog tus neeg xyuas pib Yog hais tias cov graphite hmoov raug thaiv los ntawm insulating roj hmab, nws yuav tsis ua hluav taws xob. Yog li ntawd, yog tias qhov kev faib ua feem ntawm graphite hmoov tsawg dhau, cov nyhuv conductive yuav ua rau tsis zoo.

Graphite hmoov yog ib yam khoom uas muaj rhiab heev rau cov tshuaj tiv thaiv. Nws resistivity hloov nyob rau hauv ib puag ncig sib txawv, lub ntsiab lus nws tus nqi kuj txawv. Txawm li cas los xij, muaj ib yam uas tseem nyob tas li: high-purity graphite hmoov yog ib qho ntawm cov khoom siv zoo heev uas tsis yog xim hlau. Tsuav yog cov hmoov graphite khaws cia rau hauv ib qho khoom siv insulating yam tsis muaj kev cuam tshuam, zoo li cov xov nyias, nws tseem yuav raug hluav taws xob. Tab sis tus nqi kuj yog dab tsi? Tsis muaj daim duab meej meej rau tus nqi no, vim tias qhov zoo ntawm graphite hmoov sib txawv, thiab tus nqi tsis kam ntawm graphite hmoov siv hauv cov khoom sib txawv thiab ib puag ncig kuj yuav txawv.

Post lub sij hawm: May-09-2025