Nyob rau hauv xyoo tas los no, nrog rau kev siv ntau ntawm graphite pwm, txhua xyoo tus nqi ntawm cov pwm nyob rau hauv kev lag luam machinery yog 5 npaug ntawm tag nrho cov nqi ntawm txhua yam ntawm cov cuab yeej siv tshuab, thiab cov hluav taws kub poob kuj yog heev tsis zoo rau cov uas twb muaj lawm zog-txuag txoj cai nyob rau hauv Tuam Tshoj.Qhov loj noj ntawm pwm tsis tsuas yog ncaj qha nce tus nqi ntawm cov lag luam, tab sis kuj ua rau kom nquag plias nyob rau hauv kev lag luam ntawm kev lag luam kev lag luam, tab sis kuj yuav ua rau tsis tshua muaj ntau lawm kab ntawm kev lag luam. poob.

Raws li kev soj ntsuam, vim cov pwm raw cov ntaub ntawv thiab cov nqi zog tau nce siab thiab lwm yam laj thawj, cov khoom lag luam pwm tau txais txiaj ntsig tau poob xyoo tas los; Yuav kom muaj sia nyob thiab txhim kho, ntau lub lag luam txais yuav

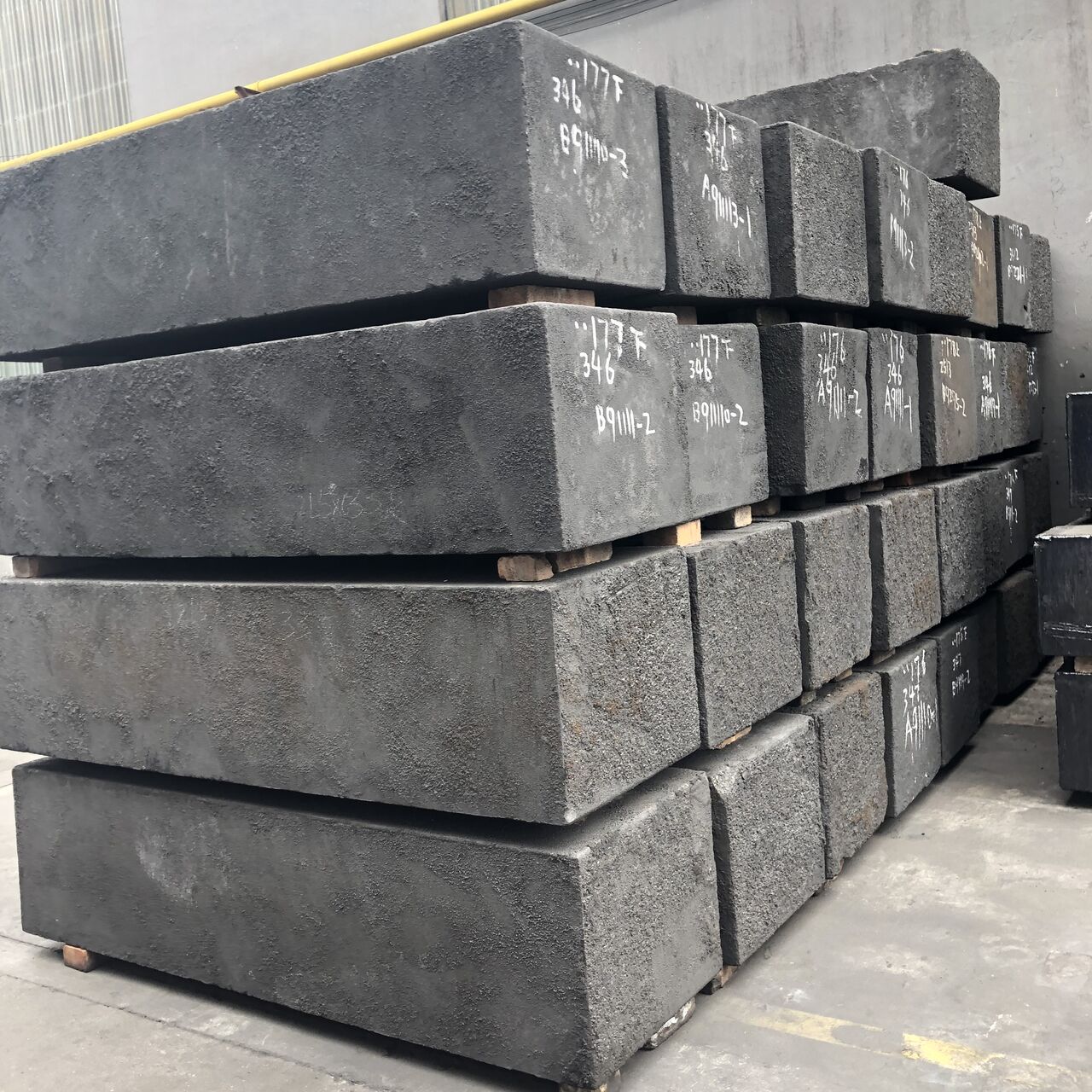

Cov khoom siv hloov pauv yog siv los ua ib qho kev ntsuas loj ntawm kev hloov pauv thiab kev loj hlob.Nws tau nkag siab tias ntau lub tuam txhab tau tsim cov khoom siv hluav taws xob graphite, hauv cov pwm tsim tau ua lub luag haujlwm tseem ceeb.Piv nrog cov tsoos tooj liab pwm, graphite cov khoom muaj qhov zoo ntawm kev ua haujlwm siab precision thiab zoo nto nyhuv, tshwj xeeb tshaj yog nyob rau hauv cov pwm kab noj hniav ntawm precision, complex, nyias phab ntsa, siab hardness cov khoom muaj ib tug zoo kawg nkaus noj qab haus huv graphite. Tawm ceev, lub teeb yuag thiab me me thermal expansion coefficient, yog li tooj liab electrode tau maj mam dhau los ua lub ntsiab ntawm cov khoom siv tawm.

1. Ceev ceev; Lub graphite tawm yog 2-3 zaug sai dua tooj liab, thiab cov khoom tsis yooj yim rau deform. Nws muaj qhov pom tseeb zoo hauv kev ua cov txheej txheem nyias nyias cov electrode. Lub softening point ntawm tooj liab yog nyob ib ncig ntawm 1000 degrees, thiab nws yog ib qho yooj yim mus deform vim tshav kub.

2. Lub teeb yuag; Qhov ntom ntawm graphite tsuas yog 1/5 ntawm cov tooj liab. Thaum cov electrode loj tau ua tiav los ntawm kev tso tawm, lub nra ntawm lub tshuab cuab yeej (EDM) tuaj yeem txo tau zoo, uas yog tsim nyog rau daim ntawv thov ntawm pwm loj.

3. Cov khoom siv me me; Raws li cov roj ntsha muaj C atoms, qhov kub thiab txias ua rau C atoms hauv cov roj ntsha ua kom decomposed thaum lub sij hawm tso tawm, thiab ib zaj duab xis tiv thaiv yog tsim nyob rau saum npoo ntawm graphite electrode, uas them rau qhov poob ntawm graphite electrode.

4. Tsis muaj burrs; Tom qab cov tooj liab electrode ua tiav, cov burrs yuav tsum tau muab tshem tawm manually. Txawm li cas los xij, tsis muaj burrs tom qab cov graphite ua tiav, uas tsis tsuas yog txuag tau ntau tus nqi thiab cov neeg ua haujlwm, tab sis kuj ua rau nws yooj yim dua rau kev paub tsis siv neeg ntau lawm.

5. Ib qho yooj yim polishing; Vim hais tias kev txiav tsis kam ntawm graphite tsuas yog 1/5 ntawm cov tooj liab, nws yooj yim dua rau grind thiab polish los ntawm tes.

Vi. Tus nqi qis; Vim qhov nce nqi ntawm tooj liab nyob rau hauv xyoo tas los no, tus nqi ntawm graphite hauv txhua yam yog qis dua li tooj liab.Raws li tib lub ntim ntawm Oriental carbon's universality, tus nqi ntawm cov khoom siv graphite yog 30% mus rau 60% qis dua tooj liab, tus nqi yog qhov ruaj khov, thiab lub sij hawm luv luv ntawm cov nqi sib txawv. kev lag luam kev lag luam, graphite electrode cov ntaub ntawv yuav maj mam hloov cov tooj liab electrode thiab ua lub luag haujlwm tseem ceeb hauv EDM.Ib yam li ntawd, nyob rau hauv kev sib tw hnyav zuj zus nyob rau hauv kev lag luam pwm niaj hnub no, kev siv cov txheej txheem ua haujlwm siab heev los tsim cov khoom pwm zoo yog txoj hauv kev zoo tshaj plaws rau cov lag luam kom yeej lub khw thiab cov neeg siv khoom.

Lub sij hawm xa tuaj: Mar-10-2021